A New Plastic Economy

… or how to pave the way to the circular economy

Think about the end at the beginning? One prefers not to do that, but when it comes to packaging design, it’s worth taking a forward-looking approach – especially when it comes to plastic packaging and recycling.

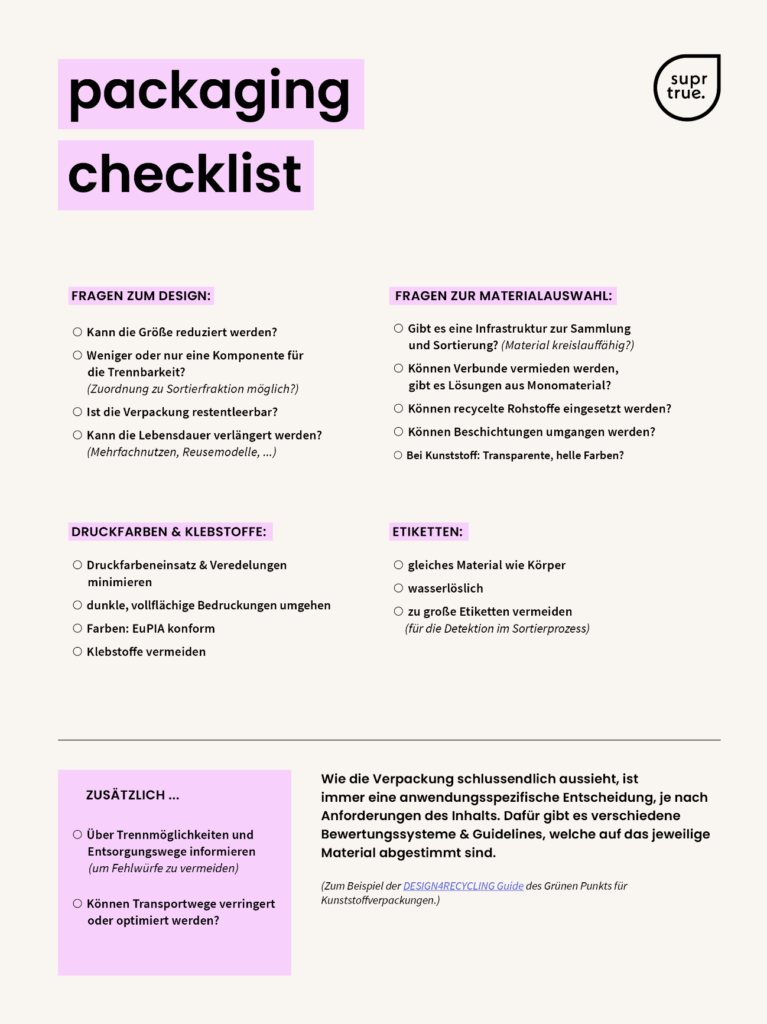

In aspiration of a circular economy, the principle of “design for recycling” is held high by designers. But what makes good recyclable plastic packaging? What design details should packaging designers pay attention to?

We take a look at the most important points and explain how the vision of the circular economy can bear fruit:

Plastic packaging still gets a bad reputation, however it is a must-have for certain products. For the vision of a circular economy for plastic to become a reality, plastic should never become waste. The Ellen MacArthur Foundation, which studies the topic extensively, describes this as the initiative of the New Plastic Economy. The vision has six goals:

Eliminate and innovate

Avoiding unnecessary and problematic plastic packaging by giving innovation a chance, developing new designs and establishing new (more efficient) delivery systems and models.

Away from single-use packaging

It is important to develop models that reduce the need for disposable packaging.

The development of better plastic

In the future, the use of plastic will be completely decoupled from the consumption of finite resources and all plastic packaging will be free of dangerous chemicals. The health, safety and rights of everyone involved are respected.

Enable and practice reuse

Ideally, all plastic packaging should be 100% reusable, recyclable or compostable in a way that is implemented in practice. Particular attention should be paid here to what the respective waste recycling plants can achieve. In practice – in Germany, as in most other countries – there is still no bioplastic composting available on an industrial level.

Furthermore, the melting points of different plastics differ enormously. PET melts at around 240 degrees Celsius, polyethylene at around 100 degrees Celsius. Consequently, recycling PET for food and beverage applications is easier as the higher temperature kills any contamination. In the case of polyethylene, only downcycling to, for example, a garbage bag, would currently be an option.

So much for the theory, but what does this mean for the producer and design industry? How can you specifically support recycling processes as a designer? Keep these principles in mind:

Principle 1 // Use light (transparent and clear) plastics.

Many sorting machines have infrared systems that can only detect light-colored (most transparent clear or transparent light blue) plastic. Colored, and black plastic is then simply sorted out into the residual waste, where it then goes into the garbage incinerator. In order to increase plastic recycling quotes, choose a light-colored plastic if possible. Clear, unpigmented PET is the easiest and cheapest to recycle. White and colored (non-transparent) bottles can contain pigments that cause contamination during recycling and result in coloring that is undesirable in the food and cosmetics sectors.

Principle 2 // A good plastic packaging can be completely emptied.

Everything else does cost recyclers additional money and means more effort, even though less valuable recyclate can be filtered out.

Principle 3 // Very important: Use mono material instead of a mix of materials.

Proper separation is the prerequisite for plastic packaging to be recycled. The combination of different materials or composites should therefore be avoided at all costs. Barrier layers can also prevent packaging from being recycled. Ideally, a single type of easily recyclable polymer is used (PE-HD, PE-LD, PP or PET). Admittedly, this is a real challenge, especially with food packaging. Since these packages have to fulfill a multitude of functions in order to ensure the durability of the products, many thin layers of different materials and plastics are often necessary. These can only be separated using state-of-the-art techniques and costs. And so we come to the next principle.

Principle 4 // Components should be able to be separated or detached without great effort.

If several materials have to be used, then all components should be easy to separate from one another. Closures, labels or sleeves should detach easily and when using glue, attention should be paid to detachability (e.g. water solubility). In order for the components to be separated successfully, transparent communication with the users is necessary. Comprehensible instructions for waste disposal are precious.

Conclusion:

There are many adjustments to be made in order to optimise the path to a circular economy with increased recycling rates. Above all, two things play an important role: On the one hand, the establishment and expansion of a functional recycling infrastructure is necessary –including modern waste collection and good sorting ability. On the other hand, clever cross-border design solutions can already make a major contribution in the right direction, or to put it another way, the focus on “design for recycling” is even more important if mature systems are still missing. Good design has the ability to change the world.

Need a detailed guideline to design for recycling? Click here.