Every brand wants a box for their products, but which one? Most of the time, they don’t know for sure. Blogger box, seeding box, shipping box, e-Commerce Box, gift box, set box, folding box, … We explain the differences and what to look out for when making your selection.

Anyone who wants to make an impression with their packaging not only pays attention to the look, but also relies on the experience that a package gives when unpacking it. “Unboxing” can be a real joy, a feeling of excitement, full of anticipation and full of curiosity, or it can cause great disappointment and thus contribute significantly to the image of a brand.

It is worth taking some time and investing to find a functional and attractive solution or ideally have it cosntructed. You want to prevent the box from being unstable and the product being damaged as a result of the material not corresponding to the value of the contents and the products sliding around in the box carelessly. Likewise, an eye for detail and fine-tuning is worth a lot.

WHAT GOES WITH YOUR BRAND AND PRODUCT?

Ask yourself the right questions and you will turn your box into a hero product:

-

Should the packaging (e.g. as an e-commerce box) be sent directly?

If so, we recommend a corrugated shipping box. These can be printed on the inside and outside and, if necessary, an insert can be inserted to fix the products. This saves you additional shipping packaging.

If you want to remain flexible and the products are not too sensitive, a filling material is recommended. Tissue paper strips with your own logo or unprinted cardboard scraps in various shapes are particularly chic. A closure label and a note card should not be missing. For a special finishing touch, there may also be some color inside or on the outside of the box. A little story can be communicated via texts inside the box or with the help of a label and note card.

-

How does your product need to be protected and how heavy is it?

Options are often excluded in this way. For very heavy or glass products, stable materials and constructions must be chosen and shipping tests must be carried out. A corrugated cardboard box is also recommended here. If the products are not sent directly, other versions are also possible, e.g. the so-called rigid box, which is, for instance, known from the mobile phone packages from Apple. It is also stable and suitable for heavy products. However, since its production is very complex, it is not the cheapest option and is therefore more suitable for high-priced products or gift sets.

-

What are the desired quantities and the timing?

We can offer a certain selection of standard folding boxes from as little as 50 pieces in a relatively short production time of approx. 15-20 working days. If you have more time and higher quantities, corrugated cardboard and rigid boxes are also an option.

Budget

It is true that the more parts, the more finishing and the higher the quality of the paper, the more expensive the box. Furthermore, the quantities are extremely decisive for better unit prices, since the set-up costs for production or the tooling or printing plate costs are always the same — regardless of whether you order 50 or 50,000 pieces.

The different boxes at a glance:

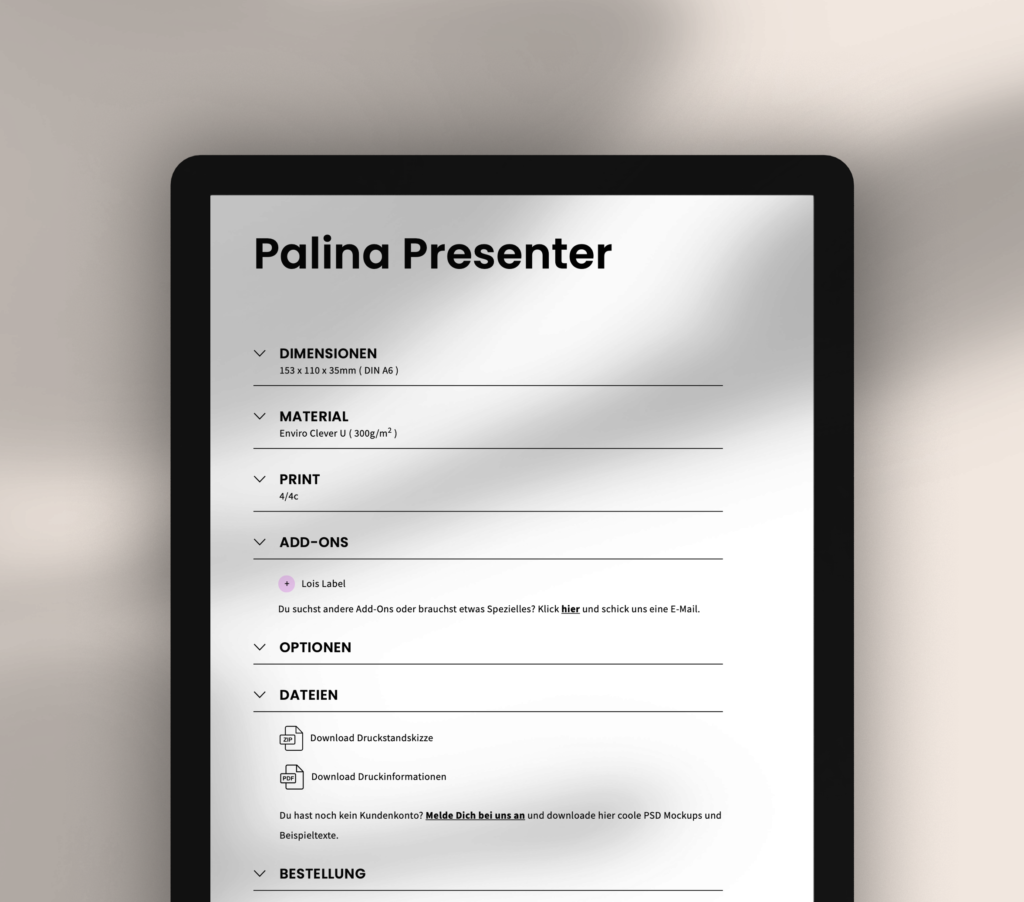

Folding boxes (various construction variants possible)

This packaging is produced flat and is particularly suitable for products that are not too heavy. The boxes can be wonderfully refined and can also be implemented in smaller quantities.

Maybe Palina Presenter is interesting for you? Check it out.

Rigid boxes

Solid cardboard blanks are covered with printed paper. The difference to a folding box is that you don’t see any folded walls, flaps or open edges. This variant is expensive, especially for small quantities and cannot be delivered flat.

Shipping boxes

Suitable for direct mail or very heavy products. Like the folding box, it is also delivered flat and can also be produced in smaller runs using digital printing.

Sustainable insert variants are e.g.: paper / cardboard insert, moulded paper or mycelium.

The latter looks like this: Molly Mycelium

Paper bag, bag pack or a paper can

Maybe it doesn’t have to be a box at all? Fashion accessories and textiles also fit well in a paper tube or a high-quality paper bag with a printed image and label. It is a stylish goodie for an event or an eye-catcher in the shop.

On the subject… you might like these suprtrue products: